CT Analysis by RX Solutions

Industrial CT or Computed Tomography is an adaption of medical CT scanning that first found practical application in the 1970s. The key principle is that of tomography. Tomography is imaging by sections through the use of a penetrating wave. The most frequent method is through radiology / X Ray.

The word tomography is derived from Ancient Greek tomos, meaning "slice, section" and graphō, "to write" or, “to describe."

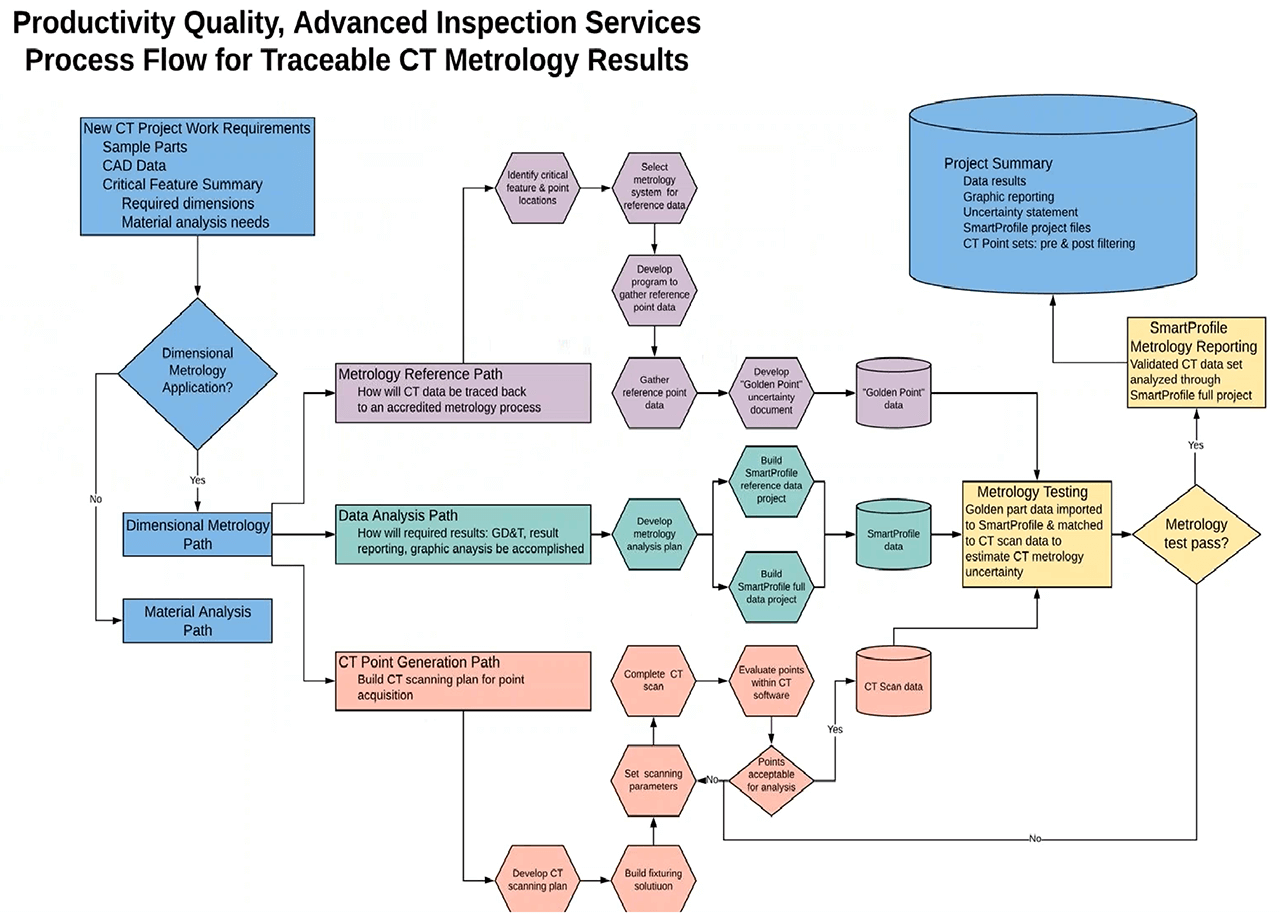

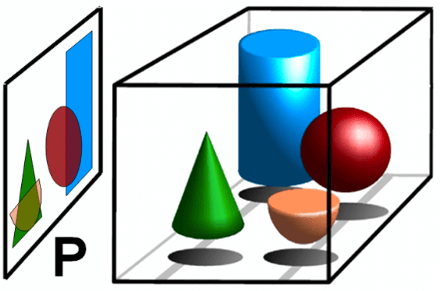

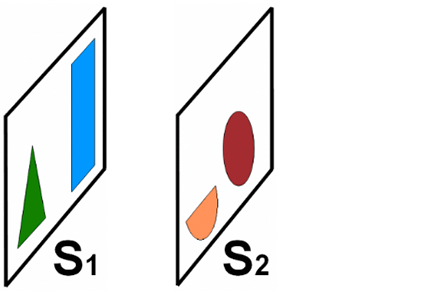

A 2D X Ray would take one of these slices as the source for its analysis. By combining multiple 2D images, a 3D image could be assembled. The most common method for gathering multiple images is through mounting the part on a rotating axis inside the CT system and taking a series of images at a specific rotational increment like every 1 degree. Early on, industrial X Ray would most often be concerned with internal defects that could affect a part’s function, like a flaw in a transmission case for a helicopter. And internal crack could lead to a part failure and cause a massive system failure and a crash. As the resolution and accuracy of industrial X Ray systems increased the sliced images could also be transformed into a 2D cloud of points and be used for measurement analysis.

Going from a single 2D image to an assembled 3D image of tens or hundreds of individual 2D images requires a complex reconstruction of the individual images into a new whole. This reconstruction process is the “Computed” of “Computed Tomography”.

A practical example of this process is the inspection of a Luer fitting. Used in thousands of fluid and gaseous sealed connections, a common Luer application is the connection between a syringe and needle or a connection between tubing like used in with an IV bag.

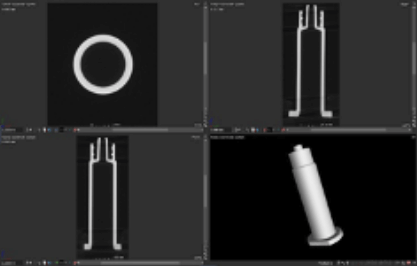

Because the manufacturing source of the male component may be different than the female component, an ISO standard has been created to insure interchangeability. The images above show Luer connections with very small internal features that must be tightly controlled to achieve a leak proof fit. CT is an ideal application for determining if the individual features meet their ISO and manufacturer’s specifications: millions of points on all internal and external sources.

The fitting of millions of points gathered through CT analysis of a Luer fitting.

Why RX Solutions CT

No one else in the industry provides this level of high performance CT Scanners with the best value, all-inclusive software and responsive support.

Every surface, internal and external, complete coverage with millions of points in only a few minutes.

Industries

Medical & Dental Aerospace Automotive Composite Electronics Injection Molding Military & Defense Oil & Gas Plastics Additive Manufacturing Academic & Research Centers Arts & Jewels