Computed Tomography, the only non-destructive technology to see inside your samples!

Additive manufactured workpieces require many controls and inspections during the overall production process. Computed tomography (CT) is a powerful non-destructive technology to inspect every samples in an easy way and the only one giving the ability to see inside the matter.

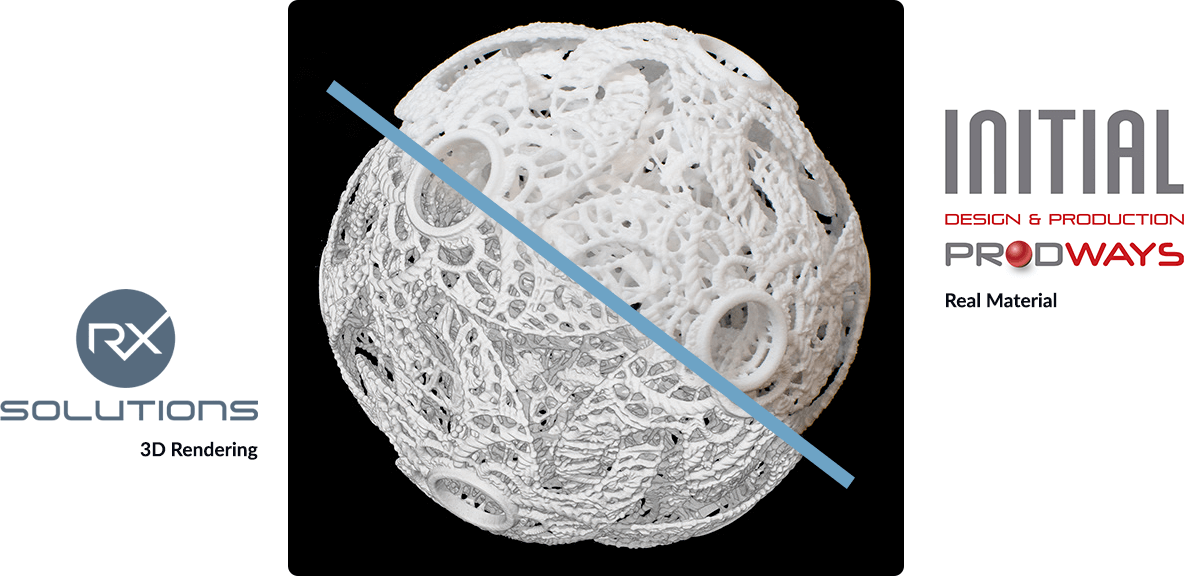

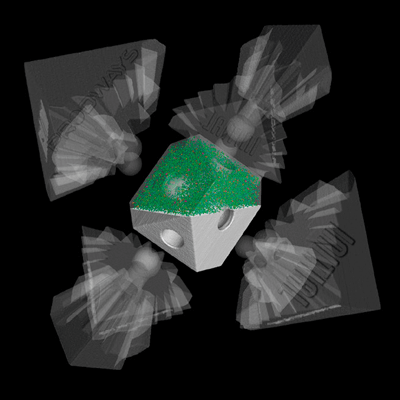

Additive manufactured part by Initial and CT scanned by RX Solutions

Computed tomography: To master 3D printed technology

Additive manufacturing opens a new affordable way to design quickly complex parts that are impossible to control and validate using traditional testing methods.

Industrial CT scanning technology is the only inspection technique able to identify in an easy way every internal characteristics of an additive manufactured part, with the ability to provide accurate measurements of the overall sample. Every structural and dimensional aspect of additive manufactured parts can be assessed through a single CT dataset.

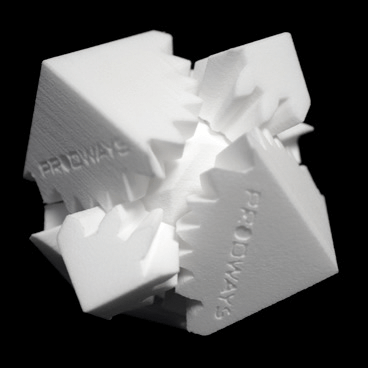

Structural analyses: Quality control validation

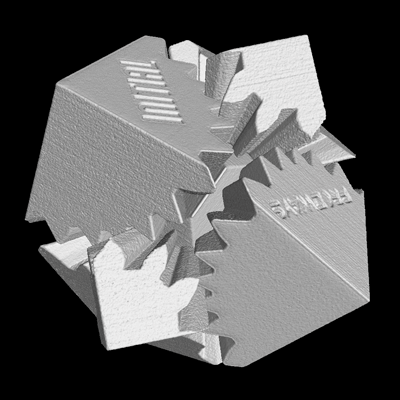

Industrial CT on 3D printed parts allows quick and accurate inspection of parts’ internal structures. With a resolution up to 5 μm, RX Solutions CT devices enable the validation of tiny details on 3D printed samples.

Even on complex printed parts, an accurate 3D model of the sample can be exported to make measurements of the inner and outer geometries on simple or multi-material printed parts.

Tomography

Post-Processing

Porosity Analysis

Many different types of analyses can be performed using CT

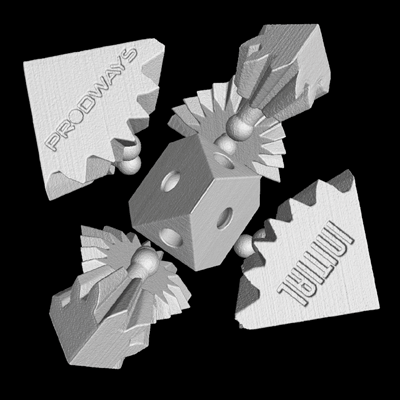

CT datasets contain the entire sample geometric information and can be used to perform different kinds of analyses: voids analysis, actual parts to CAD comparison, part to part comparison, wall thickness analysis or reverse engineering.

Material defects analyses: Porosities, inclusions, actual parts to CAD comparison

Industrial CT scanning technology allows the identification of cracks, porosities or inclusions inside the scanned parts. Defects analyses give important information on mechanical properties, that can impact components quality and influence their performance characteristics. Tomography gives the ability to detect, visualize and quantify these defects, with 3D representations.

Furthermore, a comparison between a CT dataset and a CAD nominal file can easily be made, to quickly and accurately compare the part to a CAD model by showing the external and internal deviations. Industrial CT scanning is the only non-destructive method to inspect the internal geometry of parts.

RX Solutions CT scanners: Ease of use and automation

RX Solutions provides a software plugin called “CT wizard”: it makes RX Solutions DeskTom system very easy to operate, by adjusting automatically all CT settings. In addition, in a production line environment, an automation mode will dramatically reduce the cycle time for the control by setting all CT scan parameters automatically.