Case Studies

Defect Detection Analysis with 3D Scanning Technology

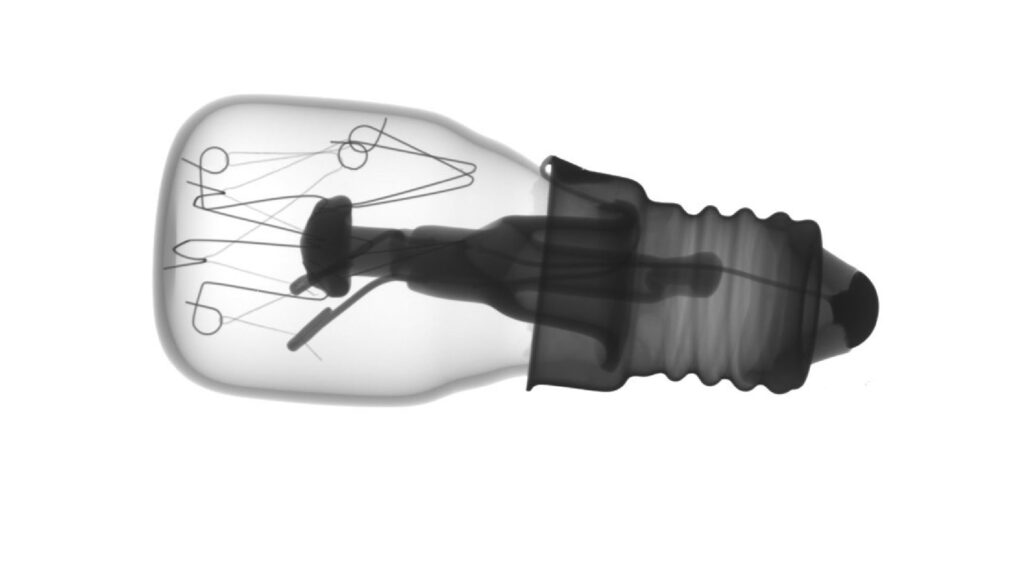

Defect Detection Analysis with 3D Scanning Technology Industrial Computed Tomography (CT) is gaining popularity as a comprehensive quality control tool in many fields and sectors for its non-destructive inspection properties. The technology also scans and collects data from complex parts with previously inaccessible characteristics and features, highlighting flaws before they become costly to resolve later…

Read MoreMaximize the Power of X-Ray Technology in Academic & Scientific Research

Maximize the Power of X-Ray Technology in Academic & Scientific Research Industrial Computed Tomography (CT) is powerful technology that digitally peels back the layers of a specimen to create a 3D model without causing any physical damage. Its non-destructive properties have led museums, life science, paleontology, and geology fields to adopt the technology to study…

Read MoreIs Industrial CT the Inspection Method for You?

Is Industrial CT the Inspection Method for You? One of the challenges facing manufacturing quality control teams from all industries is knowing what to inspect on their parts and how to inspect them. It can be difficult to know what element of a part is causing failure when you can’t see or assess it with…

Read MoreComplex Assembly Inspection with Computed Tomography

Complex Assembly Inspection with Computed Tomography Unlike other methods of inspection and non-destructive testing, X-ray tomography is not limited by part geometry and composition. It has the capability to reveal hidden features in complex parts and parts assembled from multiple components without disassembling and inspecting each individually. Comprehensive Analysis and Results To avoid part failure,…

Read MoreAdvancements for Medical Technology Part Inspection

Advancements for Medical Technology Part Inspection Evolving medical technologies have led to new devices that are held to an increasingly high standard in the design, development, and testing processes. Millions of people worldwide depend on insulin pens, implantable devices, heart stents, and capsules to live. There is no room for error when human lives depend…

Read MoreComposite Analysis with X-Ray Tomography

Composite Analysis with X-Ray Tomography Composites, being the product of two or more constituent materials, all vary in their chemical and physical structures. This variance makes composite materials ideal for use in many industrial fields, but requires inspection during the production process. The technology behind CT metrology provides a clear solution for seeing inside composites…

Read MoreIntegrating Computed Tomography into Product Development

Integrating Computed Tomography into Product Development Product development can be a lengthy process, even if you’re building on an already existing product. By the time your product is ready to go, you’ve put considerable effort, time and money into making it just right. But how do you know if it’s as right on the inside…

Read MoreInspecting Complex Aerospace Parts with X-Ray Tomography

Inspecting Complex Aerospace Parts with X-Ray Tomography In the aerospace industry, it is critical that all parts and products pass inspection without any doubt in the precision and accuracy of their configuration. X-ray tomography is an effective and efficient tool for verifying product quality and safety without damaging the part. Companies in the aerospace industry…

Read More3D Printing – Additive Manufacturing

Additive manufactured workpieces require many controls and inspections during the overall production process. Computed tomography (CT) is a powerful non‑destructive technology to inspect every samples in an easy way and the only one giving the ability to see inside the matter.

Read MoreComposites Material & Fibers

Composite workpieces require many controls and inspections during the overall production process. Computed tomography (CT) is a powerful non‑destructive technology to inspect every samples in an easy way and the only one giving the ability to see inside the matter.

Read More